Gun finishes play an important role in protecting weapons from the elements, boosting their appearance, and guaranteeing their durability. Different coatings provide differing levels of protection, longevity, and aesthetic charm, making it necessary to select the right one for your certain demands. This short article checks out numerous popular gun coatings, including Cerakote, Duracoat, Parkerizing, Bluing, and others, supplying a comprehensive summary of each.

Cerakote

Cerakote is a ceramic-based coating recognized for its extraordinary longevity and corrosion resistance. Composed of a polymer-ceramic compound, Cerakote gives a hard, protective finishing. The application procedure entails meticulous surface preparation, splashing, and healing in a stove to ensure a strong bond and a smooth, even complete. Cerakote uses impressive durability, exceptional rust resistance, and a vast array of shades and patterns for customization. It is widely made use of in both private and armed forces weapons due to its robustness and adaptability.

Duracoat

Duracoat is a polymer-based coating that attracts attention for its ease of application and customizability. It is a two-part covering system that includes a hardener for included longevity. Duracoat can be used making use of a spray gun or an aerosol can, making it available for DIY lovers. The procedure entails detailed surface area cleansing, splashing, and treating. Duracoat offers good resistance to wear and deterioration, and its substantial selection of design and colors allow special and customized finishes. While Duracoat is easier to use and extra personalized, Cerakote normally provides higher longevity and deterioration resistance.

Parkerizing

Parkerizing, likewise known as phosphating, is a chemical procedure that uses a phosphate finishing to the firearm's surface area. It has actually been extensively made use of by the armed force. The process involves immersing the firearm components in a phosphoric acid option, which reacts with the steel to develop a protective layer. Parkerizing gives exceptional corrosion resistance, a non-reflective coating suitable for military and tactical applications, and is cost-efficient contrasted to other surfaces. It is frequently made use of on military and surplus firearms as a result of its integrity and cost.

Bluing

Bluing is a traditional coating that includes creating a regulated rust layer on the weapon's surface area. The main sorts of bluing include warm bluing, chilly bluing, and rust bluing. The procedure involves immersing the firearm components in a hot alkaline solution, which causes a chain reaction that develops a blue-black oxide layer. Bluing gives a classic and cosmetically pleasing finish, moderate corrosion resistance, and is relatively simple to keep with routine oiling. It appropriates for antique and collector guns, along with modern guns that call for a traditional appearance.

Plating

Anodizing is an electrochemical process mostly used on aluminum components to raise surface firmness and rust resistance. The procedure involves engaging the light weight aluminum components in an electrolyte solution and applying an electrical existing, which develops a thick oxide layer. Anodizing offers improved surface area solidity, excellent corrosion resistance, and a range of shades for visual modification. It is commonly utilized for aluminum elements such as receivers and rails.

Nitride Finishing

Nitride ending up entails a therapy that instills nitrogen right into the surface of the metal. The major techniques consist of salt bathroom, gas, and plasma nitriding. This procedure significantly enhances wear resistance, offers exceptional defense versus corrosion, and results in an incredibly long lasting surface that calls for Read Full Article marginal upkeep. Nitride ending up is often used in high-wear parts such as barrels and bolts.

Teflon Finishing

Teflon finish uses a layer of PTFE (polytetrafluoroethylene) to the firearm's surface area, recognized for its non-stick residential or commercial properties. The application process involves splashing the Teflon remedy onto the surface area and cooking it to treat. Teflon finishing decreases friction between relocating components, supplies non-stick homes for simpler cleaning and maintenance, and supplies great chemical resistance. It is suitable for elements that require smooth procedure and simple cleaning.

Electroless Nickel Plating

Electroless nickel plating involves using a layer of nickel-phosphorus alloy to the gun without using an electric existing. This process provides consistent finish, outstanding corrosion and put on resistance, and a brilliant, attractive coating. Electroless nickel plating is utilized in firearms where harmony and improved resilience are critical, such as in interior parts and causes.

Powder Finish

Powder covering entails applying a completely dry powder to the gun's surface and afterwards curing it under warmth to form a tough surface. This procedure offers a thick and durable surface, offers lots of customization choices with a variety of shades and textures, and has ecological benefits as it utilizes no solvents. Powder finishing is thicker and much more resilient than typical paints, however may not be as described in appearance as Cerakote or Duracoat.

Verdict

Selecting the appropriate gun finish depends upon the specific demands and intended use the firearm. Each coating provides one-of-a-kind advantages in regards to protection, toughness, and aesthetic appeals. Whether you are looking for the robust defense of Cerakote, the customizability of Duracoat, or the conventional appearance of bluing, speaking with specialists can help ensure you obtain the best surface for your weapon.

Judd Nelson Then & Now!

Judd Nelson Then & Now! Shane West Then & Now!

Shane West Then & Now! Kelly Le Brock Then & Now!

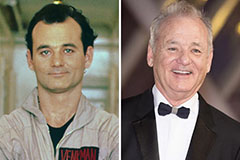

Kelly Le Brock Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!